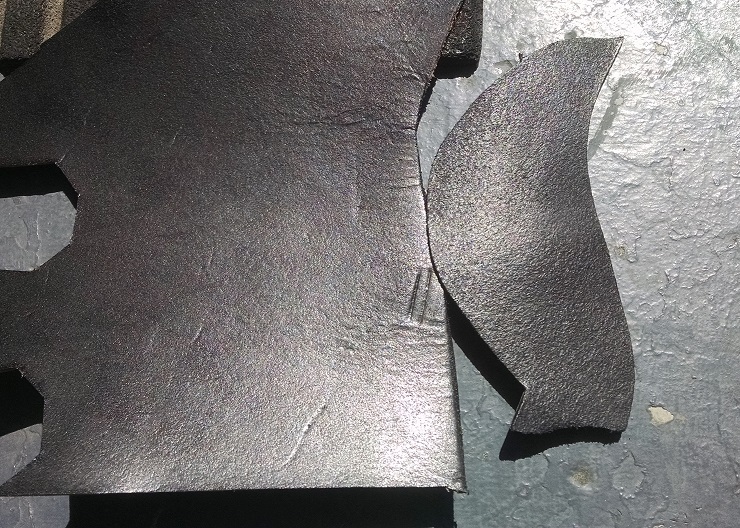

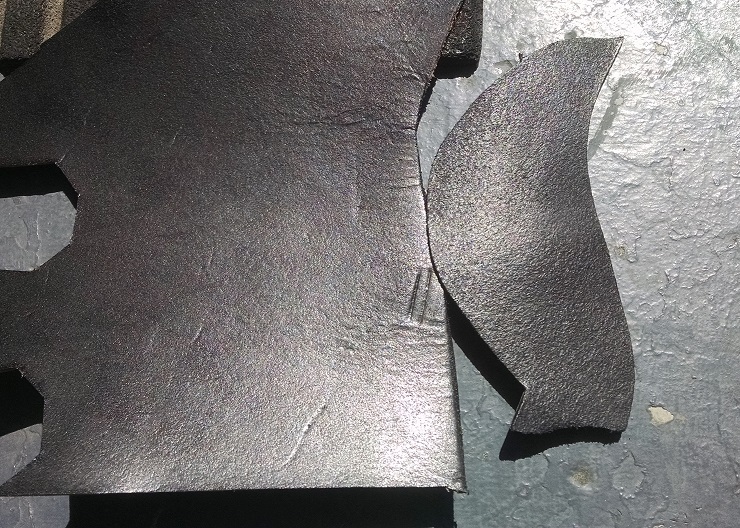

In the 18th century, leather was often dyed on the flesh (the slightly rough side), impregnated with wax, and then polished to get a sheen on it. When done correctly, it can look very similar to the grain (the smooth side), but nicks and scratches can more easily be buffed out. The last (to my knowledge) source of black waxed calf was Dickens Bros., who have since retired and are no longer producing. I recently made an attempt to make something that looks similar from regular vegetable tanned leather, though it certainly doesn’t have the hand and scent of the Dickens Bros. material. The test scrap is on the right, with the true waxed calf on the left. But, I am optimistic it will do until a new source can be found.

Making this was rather straightforward, though it remains to be seen how well it will react when having a pair of shoes made up in it.

Continue reading Quick Black Waxed Calf →

Back in June of 2011, my friend Matt and I worked up a batch of shoemaker’s wax, often called “coad” in the medieval jargon. We started with pine pitch, pine rosin, and a bit of beeswax to make some nice little balls of coad that were perfect for shoemaking. Fast forward to today, and unfortunately, our source for excellent pine pitch has dried up (pun intended). What is commonly available today is pine tar, a similar formulation, but with a great deal more volatiles still embedded, which makes it into a thick, viscous liquid rather than a gummy, solid substance. Below is experimentation to come up with some shoemaker’s wax using what we have available today. As always, if you find a source for solid, but slightly soft, gummy pine pitch, please let us know!

There are two primary sources for pine tar that I’ve used. One is the Auson Kiln-Burned Pine Tar, and the other is “The Real Stuff” pine tar, with sources in the links.

Continue reading Making shoemaker’s wax (redux) →

|

I just posted a new tutorial on Shoemaker’s Wax (Coad). Matt and I had gotten together to make some shoemaker’s wax, and I thought it might be interesting and informative to document the process.

Shoemaker’s wax is used to coat the stitching cords used in the construction process, and acts kind of like a glue. As the coated cords are pulled past each other, friction warms and melts the wax slightly. Then, when the stitch is pulled tight, the wax cools and hardens somewhat, locking the stitch in place.

|

|

I am now well supplied with actual boar bristles for the making of waxed ends used in shoemaking. The common substitute is monofilament fishing line, but once you work with boar bristles, you will never go back to monofilament! There is something about the natural fiber that makes the thread stick better, they’re splittable, and it’s what the old dead guys used. If you’re interested in some, drop me a note and we’ll talk!

I also have a large supply of synthetic coad (shoemaker’s wax) which I can make available also. At some point, I plan to actually make the real thing, and I already have all the ingredients, but there are a lot of projects to catch up on!

|

Dedicated to the Research and Construction of Chopines, Pantoufles, Zoccoli, Shoes, Boots,and Other Raised and High Heels.