A new pair of 14th century buckle shoes with a punchwork design of discs and diamonds. These are turn-welted with a pasted-in wool sock. A whipped-in stiffener and brass buckle complete the piece. Looking back, I think that these shoes would look better with a more pointed toe, but perhaps that is the medievalist in me jumping out =) In truth, there is evidence for a variety of shoe types in the 14th century, both round and pointed, but I must admit some partiality to the gothic points.

All posts by raisedheels

Viking Shoes based on finds in York…

Jumping back several centuries, I present you a pair of Viking shoes based on finds in York. The leather was curried with cod liver oil and tallow, and I really like the way that they came together. It’s hard to see in this image, but the heel extends in a triangle in the back like many Viking shoes. There is a felt wool sock pasted in. A few interesting things on these shoes besides the currying – the straps are held in by tension alone – no sewing. That is, three slits are cut in the leather and the thongs are laced through them with a snug fit. This allows the wearer to adjust the position of both toggles and straps, and to easily replace them should they be torn or damaged. This technique was also done in the 16th century with shoes found on the Mary Rose, sunk off the Solent in 1545.

Currying Leather Properly…Part II

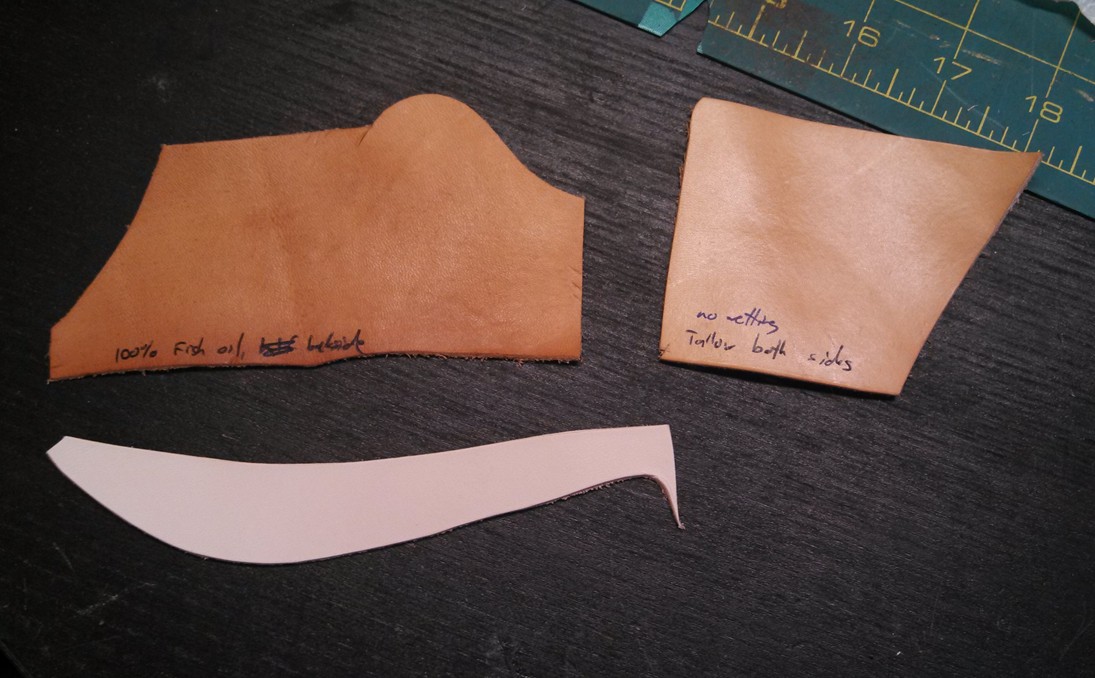

After looking at the four pieces, I discovered that there was something of a difference between the piece of leather that had been oiled on both sides rather than just the front, so I decided to go with just the one which had been oiled on both sides. For the tallow, there might have been a slight difference in tallowing leather that had been wet – it didn’t take the tallow as well. As a matter of course, you kind of want as much oil and grease in the leather as you can get, which will keep it in the best shape. So, dry is certainly the way to go, and you will get more tallow into it when dry.

I also noticed that to get a rather darker look than I was looking for, I had to apply a couple of coats of fish oil. I also found that if you dunked the leather in a bucket, it did NOT take the fish oil very well, so I ended up simply spritzing it down with a spray bottle and using a rag to apply the fish oil. Essentially, the dryer your leather is, the darker the oil will make it look. Dark leather is lovely, but you don’t want streaky dark leather, so I would err on the side of a bit of dampness and several applications. I let this leather sit for about three weeks, and although I am told that it is supposed to “jelly” up a little, I did not notice a significant difference. Possibly, I did not oil the leather enough. In any event, you can see below the leather I started with and how much darker it is now. Quite a difference!

However, tallowing made the leather beautifully supple and smooth – I cannot say at this time if the leather will retain its suppleness and smoothness over time or if the tallow will leech out too quickly, but I will be sure to keep you in the loop and update this post accordingly. From now on, all of my shoes will be at least tallowed, if I do not have the time to oil them as well. Neatfoot oil might have a similar effect, but it is modern, and I’d rather go for something that has some historical appeal to it. We are, after all, reproducing history!

Currying Leather Properly…Part I

It’s been a while since I posted something on the topic of actual shoemaking rather than just showing off finished products, and we’re long overdue. I’m going to talk a bit about currying leather.

It’s not what you think – I’m not going to the Indian market to pick up the proper spices. Nor am I performing a mathematical transformation of a function with multiple arguments into a chain of functions, each with a single argument. In fact, the verb “to curry” is actually much older, and comes from the 13th century, from the Middle English currayen, from Anglo-French cunreier or correier, which was to prepare, curry, from Vulgar Latin conredare. It means to dress tanned hides by soaking, scraping, beating, etc. in order to make them supple and resistant to water. So, how does one do this, exactly? First, a history lesson…